Waste Management at MEPL

Hazardous Waste

Transportation

Scientific Storage

Disposal

Waste destruction

Recovery

Scientific closure

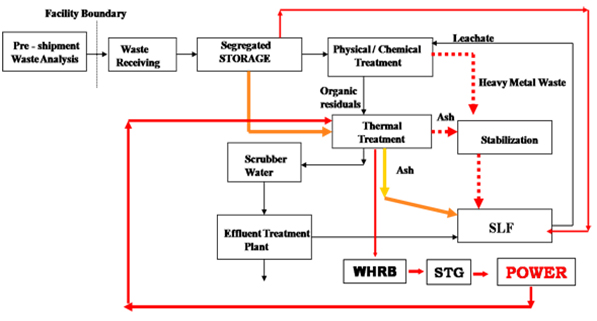

Process

Direct Land Filling (DLF)

We have Secured landfill which meets criteria for hazardous waste landfill as per CPCB guidelines. The location and design of the landfill have been approved by competent authorities. Systematic operation of landfill ensures that environment around is not adversely affected. Monitoring of environment with respect to air, soil and ground water is regularly done to ensure compliances as per prescribe norms.

During the monsoon period filled up waste in the secured landfill is covered by HDPE film to protect contamination of ground water. SLF will be suitably covered as prescribed once it is filled up with waste. Prior to accept any hazardous waste Comprehensive Analysis Report (CAR) is taken from generator and for every hazardous waste consignment Finger Print Analysis is done and compared with CAR and disposal pathway is finalized. Post closure monitoring is done for all landfills.

Solidification & Stabilization

Few types hazardous waste has characteristics leading to leaching of toxic contents like metals etc. these wastes have to be properly treated with specific chemicals and binders to prevent leaching of undesirable materials our TSDF designed and installed an automatic and mechanically operated system for stabilization process, where by toxic materials are immobilized by binding with cement, fly ash, bentonite, hydrated lime and other specialized chemicals to achieve waste having characteristics which can be safely land filled.

Post stabilization analysis is done prior to disposal of waste in landfill to check whether waste is suitable for landfill.

Plasma Gasification

Plasma is often referred as to the ‘Forth State of Matter’. It is formed by passing an electrical discharge through a gas. Plasma torches are capable of producing temperatures nearly as hot as the suns surface.

Gasification occurs when carbon containing feed stocks is exposed to extremely high temperatures (over 5000 C) in the presence of controlled supply of air to generate a wide variety of high value energy outputs. It creates hydrogen and carbon monoxide which is an energy rich gas stream. Gasification is not incineration. The gasification process is environment friendly. The gaseous emissions meet stringent CPCB norms and/ or practically free of dioxins and furans. Inorganic salts contain in the waste material are converted into vitrified slag which is non hazardous and can be gainfully used for various purposes like paver blocks, bricks, road making etc.

The energy rich syn gas is combusted and heat is recovered in waste heat recovery boiler to produce high pressure steam which is fed to turbine for generating electrical power and MEE operation.